Insgesamt 380.000 Liter grünes Benzin (E-Fuel) plant ein Konsortium aus Forschung und Industrie, darunter auch Teams der TU Bergakademie Freiberg und der Chemieanlagenbau Chemnitz GmbH (CAC), in den kommenden vier Jahren herzustellen.

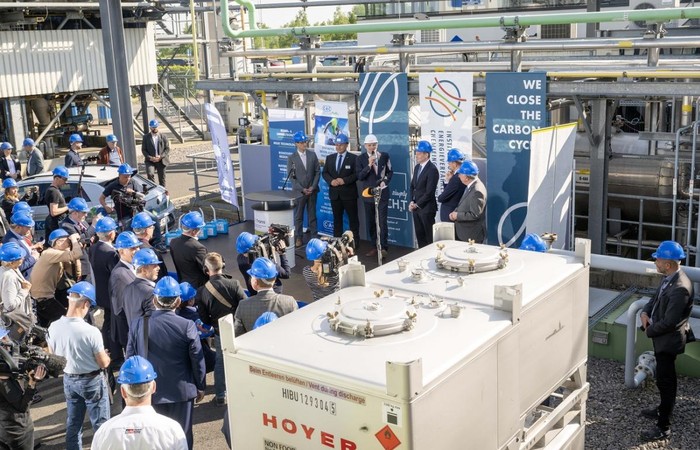

Der synthetische Kraftstoff wird in einer Demonstrationsanlage im sächsischen Freiberg aus biogenem oder regenerativ gewonnenem Methanol erzeugt. Am 25. Mai wurden die ersten im Vorhaben produzierten 15.000 Liter des synthetischen Benzins an der Pilotanlage abgeholt.Mit der Produktion des E-Fuels über den geplanten Zeitraum von vier Jahren soll das Projekt demonstrieren, dass mit Hilfe einer Kohlenstoffkreislaufführung eine bis zu 90-prozentige CO2-Einsparung möglich ist. Gefördert wird das Verbundprojekt „Demonstrating a Circular Carbon Economy in Transport along the Value Chain“ – kurz DeCarTrans – vom Bundesministerium für Digitales und Verkehr (BMDV).

Zusammenarbeit mit Industrie in Sachsen

Das Teilprojekt der TU Bergakademie Freiberg wird in enger Zusammenarbeit mit dem Technologiegeber CAC realisiert und erhält eine Förderung von 12,78 Millionen Euro. Die ersten im Rahmen des Projektes erzeugten 15.000 Liter des synthetischen Benzins wurden am 25. Mai an der Demonstrationsanlage bereitgestellt. „Nach dieser initialen Versuchsfahrt wird die an der TU Bergakademie Freiberg betriebene Benzinsynthese-Großversuchsanlage mit einer optimierten Produktaufbereitung ausgerüstet, die eine weitere Verbesserung der Benzinqualität ermöglicht“, erklärt Prof. Martin Gräbner. „Danach soll in weiteren mehrmonatigen Versuchskampagnen die Dauerbetriebsfähigkeit des Produktionsverfahrens bestätigt werden“, so der Projektleiter und Inhaber der Professur für Energieverfahrenstechnik.

Zur Anwendung des Verfahrens erklärt Jörg Engelmann, Geschäftsführer CAC: „Voraussetzung für die Umsetzung als industrielle Großanlagen sind politische Weichenstellungen, um den Investoren die notwendigen Sicherheiten zu geben. Nur mit Technologieoffenheit und schnellen Entscheidungen lassen sich die Klimaziele im Verkehrssektor erreichen.“ CAC als Technologiegeber dieser Benzinsynthese bringt langjährige Kompetenz als Engineeringunternehmen für die Planung und Umsetzung von komplexen Chemieanlagen ein. Ausgehend von Methanol, das u. a. aus Kohlendioxid (CO2) und „grünem“ Wasserstoff (H2) hergestellt werden kann, hat CAC den patentierten Prozess entwickelt. „Wir freuen uns mit diesem Projekt, den angestrebten Dauerversuchen und Umbaumaßnahmen die Marktreife unserer Technologie zu bestätigen und weiter zu verbessern“, so Engelmann.

Weiterhin wollen die Forschenden an der TU Bergakademie Freiberg verschiedene Qualitäten regenerativ hergestellten Methanols testen. Auch die benötigten Katalysatoren werden an der Freiberger Professur für Reaktionstechnik optimiert, um die Produktion noch effizienter zu machen.

Produktion im Dauereinsatz betreiben

Bis 2026 sollen 380.000 Liter Benzin produziert werden, die dann den Projektpartnern für Kraftstoffuntersuchungen sowie umfangreiche Kfz-Tests zur Verfügung gestellt werden.

Die Großversuchsanlage für synthetisches Benzin wurde 2009 als bundesweit erste und größte ihrer Art von CAC an der TU Bergakademie Freiberg errichtet. Im Rahmen mehrerer Forschungsprojekte, gefördert vom Bund, dem Freistaat Sachsen sowie mit Eigenmitteln der CAC, konnte bis 2023 die Entwicklung weiter vorangetrieben, die Technologie patentiert und für die Großproduktion vorbereitet werden. Das nun laufende, vom BMDV geförderte DeCarTrans-Verbundvorhaben ermöglicht es, die Benzinsynthese im Dauereinsatz zu betreiben und Kraftstoffe in für Demonstrationszwecke ausreichenden Mengen zur Verfügung zu stellen.

Wissen für die Praxis schon im Studium anwenden

Studierende an der TU Bergakademie Freiberg profitieren von der aktuellen, anwendungsnahen Forschung: In Studiengängen wie Verfahrenstechnik und Chemieingenieurwesen (Diplom) oder Engineering (Bachelor) lernen sie beispielsweise, wie man aus Agrarreststoffen nachhaltigen Kraftstoff herstellen kann. Ihr Wissen können sie an den einzigartigen Demonstrationsanlagen der Universität praktisch anwenden. Das macht die Absolvent:innen zu gefragten Expert:innen für wirtschaftliche und klimaneutrale Umwandlungstechnologien. Viele sind später in der Industrie tätig und bringen ihr Wissen bei Unternehmen, wie CAC ein, um Technologien der Zukunft voranzutreiben.

Über das Forschungsprojekt DeCarTrans

Zu den geförderten Partnern des Projekts Demonstrating a Circular Carbon Economy in Transport Along the Value Chain (DeCarTrans) gehören neben der TU Bergakademie Freiberg und Chemieanlagenbau Chemnitz GmbH die FEV Europe GmbH, Hermann Lother & Co. Mineralölhandelsgesellschaft mbH, Coryton Advanced Fuels Deutschland GmbH und Forschungszentrum Jülich GmbH. Weitere Unternehmen aus den Automobil- und Mineralölbranchen unterstützen das Projekt als assoziierte Partner.

Das Projekt DeCarTrans wird im Rahmen des Gesamtkonzepts Erneuerbare Kraftstoffe mit insgesamt 14,93 Millionen Euro durch das Bundesministerium für Digitales und Verkehr gefördert. Die Förderrichtlinie für die Entwicklung regenerativer Kraftstoffe wird von der NOW GmbH koordiniert und durch die Projektträger VDI/VDE Innovation + Technik GmbH sowie die Fachagentur Nachwachsende Rohstoffe e. V. umgesetzt.

Hintergrund zu E-Fuels

E-Fuels sind mit erneuerbarem Strom synthetisch hergestellte flüssige Kraft- oder Brennstoffe, mit denen PkW (weltweit 1,2 Mrd.), Lkw, Flugzeuge, Schiffe oder Heizungen – alles, was einen Verbrennungsmotor hat – klimafreundlich betrieben werden können. Werden E-Fuels in Reinform eingesetzt, lassen sich die CO2-Emissionen um bis zu 90 Prozent gegenüber mineralischen Kraftstoffen verringern. Zudem können E-Fuels flächendeckend über das bestehende Tankstellennetz zur Verfügung gestellt werden und sind speicher- sowie transportfähig.

In Methanol-basierten E-Fuel-Prozessen besteht ein weiterer Vorteil darin, dass die Produktion des Methanols an Standorten erfolgen kann, wo regenerativ erzeugter Strom als wesentlicher „Rohstoff“ reichlich und damit günstig zur Verfügung steht. Damit wird sichergestellt, dass erneuerbare Energien in großen Mengen nach Deutschland und Europa importiert werden können, um den Energiebedarf langfristig nachhaltig zu decken.

Das im DeCarTrans-Vorhaben aus Bio-Methanol erzeugte drop-in-fähige synthetische Benzin erfüllt als E10-Blend die Anforderungen der Norm DIN EN 228, wird nach REACH registriert und kann konventionellen fossilen Kraftstoff direkt ersetzen oder ihm beigemischt werden – ohne technische Anpassungen am Fahrzeug. In einer industriellen Anlage könnten heute schon Herstellungskosten von unter 1 Euro pro Liter erreicht werden.

Über CAC

Zuverlässig, erfahren und menschlich ist CAC ein international führendes Unternehmen für Anlagenbau in der Prozess- und Verfahrenstechnik. In den Geschäftsbereichen Chlor-Alkali-Elektrolyse, nachhaltige Power-to-X-Lösungen, Kohlenwasserstoff-Technologien und Chemische Industrie bietet CAC das gesamte Leistungsspektrum eines Engineering- und Anlagenbauunternehmens an. Seit 2008 entwickelt CAC an synthetischen Kraftstoffen und hat in Freiberg Europas größte Demonstrationsanlage zur Herstellung synthetischen Benzins errichtet.

Mit rund 400 Mitarbeitern, 270 am Unternehmenssitz in Chemnitz, hat CAC in mehr als 55 Jahren weltweit über 500 Industrieanlagen errichtet. Mehr Informationen zu Chemieanlagenbau Chemnitz GmbH erhalten Sie unter: www.cac-chem.de

Seit 2005 ist HUGO PETERSEN GmbH, weltweit größter Technologiegeber für Schwefel- und Salzsäureherstellung sowie Gasreinigungsprozesse, Teil der CAC Group of Companies. 2006 wurde das Portfolio um das Engineeringunternehmen BiProTech Sp. z.o. o. als zweite Tochtergesellschaft ergänzt.

Fragen beantwortet / Contact: Prof. Martin Gräbner